MARKET OVERVIEW:

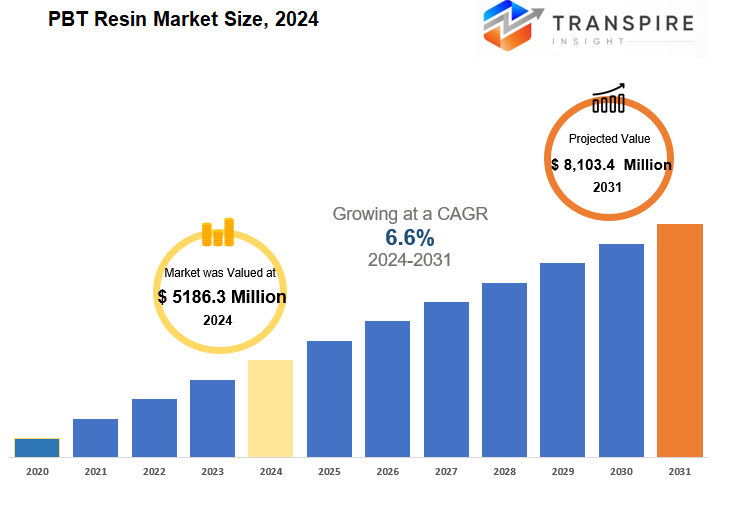

Global PBT Resin market is estimated to reach $8,103.4 Million by 2031; growing at a CAGR of 6.6% from 2024 to 2031.

The global PBT resin market is dominated by high-performance thermoplastics, particularly PBT resin, which is used in automotive, electronics, and consumer goods industries due to its superior mechanical properties, chemical resistance, and thermal stability. In the automotive sector, the demand for light materials to make more fuel-efficient vehicles will drive the production of PBT resin for components like electrical connectors and housings. The electronics industry will also see growth in PBT resin usage for components like circuit boards, connectors, and insulators due to its thermal stability and electrical insulating properties.

Furthermore, PBT resin's versatility will benefit the consumer goods industry by providing longer lifespan and wear resistance in products such as household items, appliances, and packaging. The industry is moving towards developing bio-based PBT resins to meet increasing environmental concerns and appeal to environmentally conscious customers.

Research and development in PBT resins have led to improvements in properties, resulting in special grades for specific applications. The market will be competitive with established players and new entrants focusing on innovative products and green practices through joint ventures and partnerships. Overall, the global PBT resin market will be characterized by significant contributions across industries driven by the demand for high-performance materials.

GROWTH FACTORS

The global PBT resin market is expected to grow due to increased demand in the automotive industry and higher usage in electrical components. PBT resin is valued for its light weight and durability, making it popular for manufacturers aiming to improve product efficiency and performance.

In the automotive sector, lighter materials like PBT resin are sought after to enhance fuel efficiency and reduce vehicle weight. Additionally, PBT resin's insulating properties make it essential for electronics as products become smaller and more sophisticated. However, challenges such as fluctuating raw material prices and competition from other engineering plastics may hinder the market's growth.

Despite these obstacles, the future of the global PBT resin market looks promising, with opportunities arising from the trend towards miniaturization in electronics and the demand for higher-performance materials. The market's prospects in segments like automotive and electronics will be driven by innovation and performance in the coming years.

MARKET SEGMENTATION

By Type

The Global PBT Resin market is growing rapidly due to increased demand from various sectors. PBT resin is favored for its thermal stability, chemical resistance, and mechanical strength, making it ideal for automotive, electrical, and consumer goods applications.

The market is evolving with manufacturers innovating to enhance performance and meet specific customer needs. The market is divided into reinforced and unreinforced PBT resin types. Reinforced PBT resin, which includes additives like glass fibers, is in high demand for applications requiring high mechanical strength, such as automotive components. Unreinforced PBT resin, known for its flow properties, is used in applications like domestic appliances and electronic parts.

Advancements in production technologies and materials will drive the market in the future, focusing on sustainability and environmental impact reduction. The increasing use of electric vehicles and renewable energy technologies will also boost demand for specialized PBT resin products.

By Processing Method

The PBT Resin market plays a crucial role in the materials industry, showing potential for growth and innovation worldwide. PBT, or Polybutylene Terephthalate, is a thermoplastic engineering polymer with excellent mechanical properties, chemical resistance, and thermal stability.

Injection molding is a widely used processing technique in the industry, ideal for creating complex and accurate automotive and consumer products. Extrusion is another critical technique, producing shapes like sheets, films, or pipes for construction and packaging industries.

PBT is popular for producing hollow plastic parts, such as containers and bottles, due to its lightweight yet strong properties. Other methods like 3D printing and thermoforming offer new possibilities for custom work and rapid prototyping, diversifying PBT applications in various industries. Advancements in technology will continue to drive the development and use of PBT in the future.

By End User

The Global PBT resin market is growing rapidly due to high demand in various sectors like automotive, electrical and electronics, consumer appliances, industrial machinery, medical devices, and packaging.

PBT resin is a strong and durable thermoplastic polymer used in different industries for its performance benefits. In the automobile industry, PBT resin is preferred for parts like interior and exterior components, electrical system housings, and connectors to improve fuel efficiency and reduce emissions.

In the electrical and electronics sector, there is an increasing need for lightweight and durable materials like PBT resin for items such as connectors, switches, and housing. Consumer appliances, medical devices, and packaging industries are also using PBT resin due to its functional and aesthetic advantages. As more industries seek superior and sustainable materials, the demand for PBT resin will continue to rise with opportunities for growth and innovation in the market.

REGIONAL ANALYSIS

The PBT resin market is growing globally, with North America, Europe, Asia-Pacific, South America, and the Middle East and Africa being key regions. North America, including the U. S. , Canada, and Mexico, has a high demand for PBT resin in industries like automotive, electronics, and consumer goods.

The focus on lightweight materials for fuel efficiency in the automotive sector is driving demand for high-performance resins like PBT. In Europe, countries like the UK, Germany, France, and Italy lead the market, with a focus on sustainability and innovation in PBT resin production. The Asia-Pacific region, including China, India, Japan, and South Korea, is expected to experience significant industrial growth, leading to increased demand for PBT resins. South America, particularly Brazil and Argentina, is also seeing growth in PBT resin consumption due to economic and industrial development.

The Middle East and Africa are emerging players in the PBT resin market, with opportunities in construction and automotive sectors. Overall, the global PBT resin market is still in a growth phase, with each region leveraging its strengths and market dynamics to drive demand and application.

KEY INDUSTRY PLAYERS

The PBT resin market globally is dynamic, with key players like SABIC, BASF SE, and Celanese Corporation investing in R&D to develop new solutions for customers, particularly in automotive and electronics.

BASF focuses on environmentally friendly PBT resins, while Celanese Corporation focuses on high-performance materials. Clariant AG and Daicel Corporation are driving market growth through innovation and partnerships. Other major players include DuPont and Evonik, known for their research capabilities and advanced materials. LG Chem, Mitsubishi Chemical, and Lanxess AG are also investing in PBT resin production to meet growing demand. The market is expected to continue to grow as key players introduce new technologies and initiatives to meet the needs of a sustainability-focused world.

REPORT SCOPE AND SEGMENTATION

|

Attributes |

Details |

|

Market Size By 2031 |

USD 8,103.4 Million |

|

Growth Rate |

CAGR of 6.6% |

|

Forecast period |

2024 - 2031 |

|

Report Pages |

250+ |

|

By Type |

|

|

By Processing Method |

|

|

By End User |

|

|

By Region |

|

|

Key Market Players |

|

_page-000143.jpg)

_page-000149.jpg)

_page-000148.jpg)

_page-000147.jpg)

_page-000146.jpg)

APAC:+91 7666513636

APAC:+91 7666513636